Mold Cooling Channel Cleaner

เครื่องล้างตะกรัน

Brand: MIZUKEN

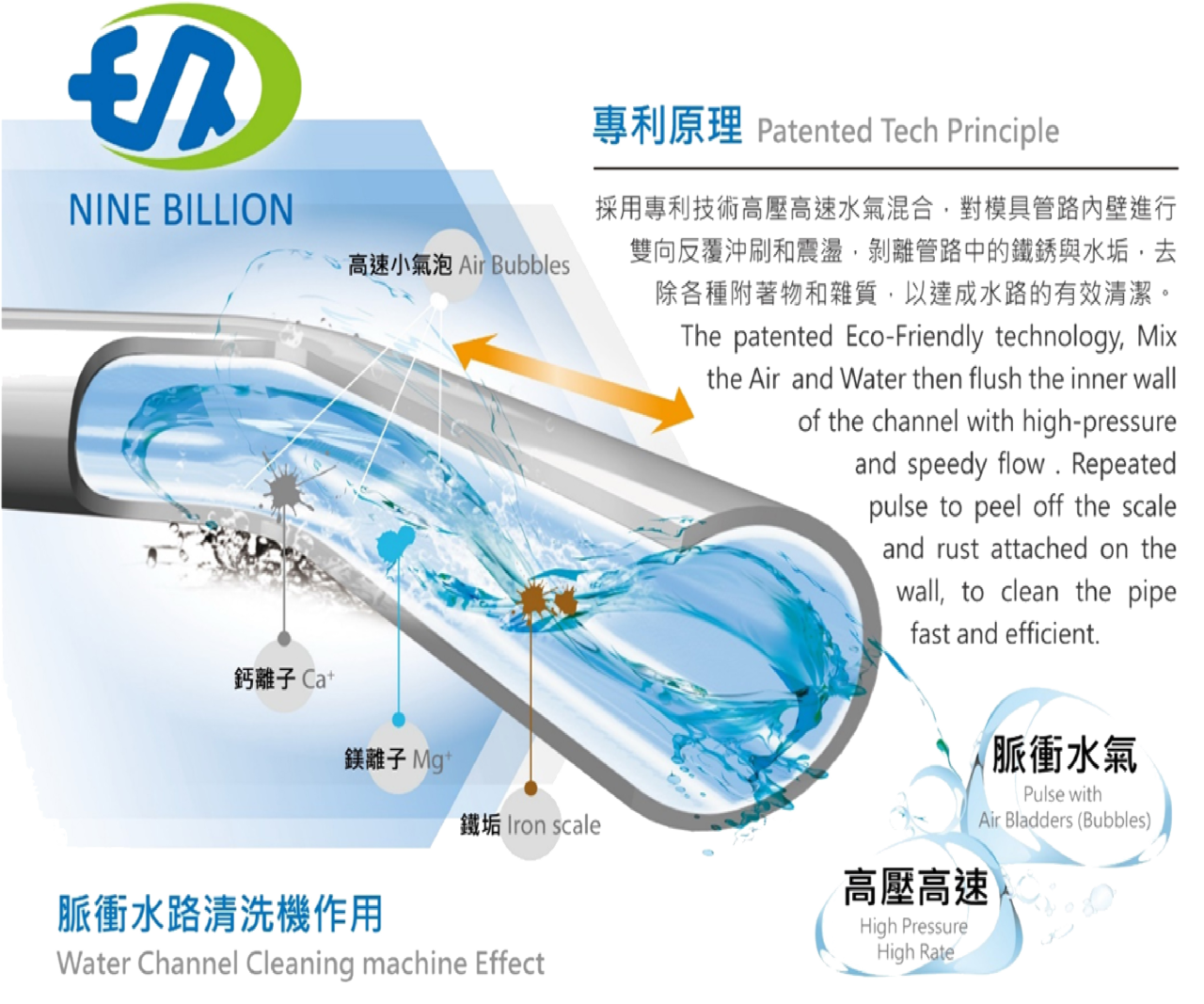

The waterway cleaning machine of Shuiken mold adopts patented technology. Through the pulse controller, the compressed air acts on the water flow in the form of pulses, which generates spiral shearing force along the inner wall of the pipe, and frequently produces the phenomenon of “cavitation”. Under the action of alternating pressure, water causes the bubbles in it to burst, resulting in micro-jet impact and shock wave impact. This jet can form a huge impact on the solid surface and can produce local surface damage, and the jet and bubble burst The generated waves act together on the solid surface at high speed and high pressure, eroding it, removing the scale layer and brittle debris, and enabling the inner wall of the pipeline to be effectively cleaned.

Using high-pressure and high-speed water-air mixing, the inner wall of the mold pipeline is scoured and oscillated repeatedly in two directions, peeling off the rust and scale in the pipeline, removing various attachments and impurities, so as to achieve effective cleaning of the waterway.

Factory Common Trouble

Scale and rust buildup

Product warpage deformation, forming cycle lengthening, quality and productivity decline

Production interruption downtime

Scale clogging, mold, and equipment temperature rise, resulting in downtime

Pipeline scratches caused by traditional manual cleaning methods

Pipes are easily damaged, scratches take a long time, and the labor intensity is high

Chemical cleaning method mold is vulnerable to corrosion

Long-term use causes mold corrosion and requires repeated cleaning with multiple agents

Pulse Water Cleaning Machine – Advantage

– Applicable to various types of machines and equipment.

– The pipeline is cleaned in pulses without scratching or eroding the inner wall of the pipeline.

– Waterway cleaning is quick and easy.

– The machine equipment is connected quickly and easily with the waterway cleaner.

– It can perform flow detection and cleaning record management.

Pulse Water Cleaning Machine – Features

Pulse technology, efficient cleaning without hurting the pipeline

Through the pulse controller, the compressed air acts on the water flow to generate a spiral shear force along the inner wall of the pipe, and the phenomenon of “cavitation” occurs frequently.

Under the action of alternating pressure, water causes the bubbles in it to burst, resulting in micro-jet impact and shock wave impact. This jet can form a huge impact on the solid surface and can cause surface damage.

Scale Removal & Rust Removal, Simultaneous and Efficient Processing

Soft scale: As long as you use clean water to clean with high pressure and high-speed pulse, it can be easily and quickly removed.

Hard scale: adding 5% sulfamic acid (similar to citric acid) can effectively soften the scale and remove it completely.

The patented neutral rust remover (PH 6.8-7.0) developed by Shuiyan can be added to the water tank of the washing machine simultaneously, and the descaling and rust removal are carried out simultaneously.

Pulse Water Cleaning Machine – Benefit

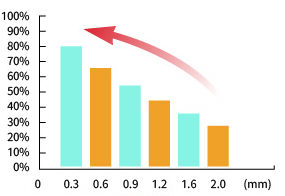

Improve mold cooling circulating water flow and heat exchange efficiency

1. Strengthen production efficiency

2. Shorten molding cycle

3. Increase product yield

Pulse water cleaning machine – practical application

What field is the mold water cleaning machine suitable for?

Suitable for injection molding, die casting, extrusion, blow molding, and other mold forming fields, such as auto parts, home appliances, medical equipment, perform packaging, electronic accessories, and other industries.

How to choose a cleaning machine model?

There are two reference objects for model selection, the actual water storage capacity of the mold and the size and quantity of the inlet and outlet pipe diameters of the mold. You can refer to the comparison model table or consult Xingchuang Technology.

How to judge the effect of mold cleaning?

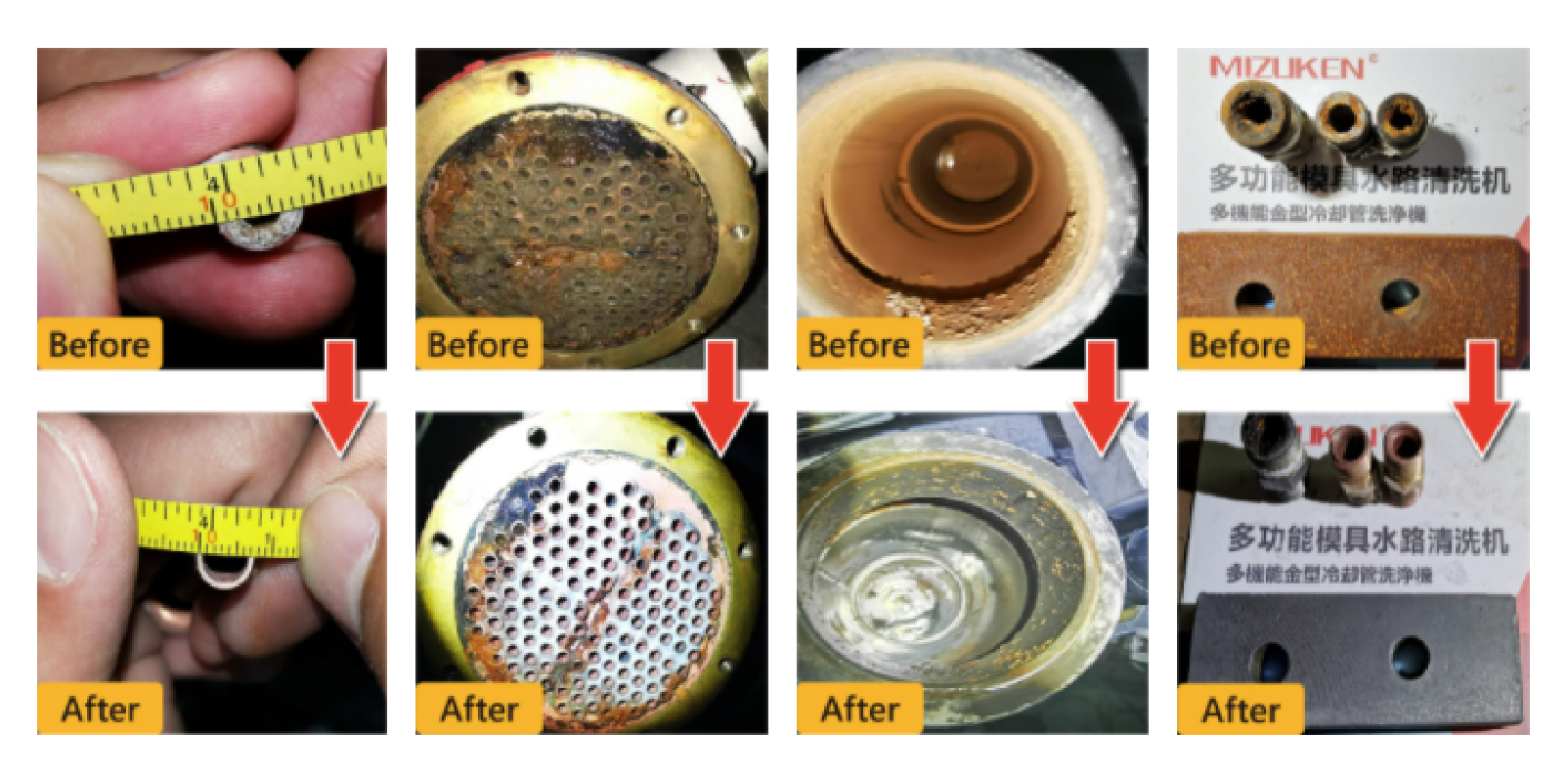

– Comparison of photos before and after mold pipeline cleaning.

– The water becomes dirty, and the rust, impurities, etc. are cleaned out.

– Changes in flow before and after cleaning.

What is the chemical composition of the cleaning agent? Does it corrode the mold or harm the human body?

The cleaning agent is industrial grade sulfamic acid, white powder, mainly to soften calcium and magnesium carbonate scale, almost no reaction and corrosion to seals, etc., and can be directly contacted with human skin without hindrance.

Can the mold oil circuit be cleaned?

The cooling oil circuit can be cleaned by using the special oil circuit cleaning agent of Shuiyan Technology, but the water circuit and the oil circuit cannot share the same cleaning machine (one cleaning water circuit and one cleaning oil circuit), and water cannot be used directly as the medium. Cleaning to avoid emulsification and deterioration of heat transfer oil.

Office

Minnotec Thailand Co.,Ltd.

Kanya Building (A4)

999 Soi King Kaew 17, Ratchathewa Subdistrict, Bang Phli District, Samut Prakan 10540

Line official

@940ovfau

Contact number

+66 2 - 118 - 2586 (TH)

ACMT Thailand

ACMT Global