Internet of Molding (IoM)

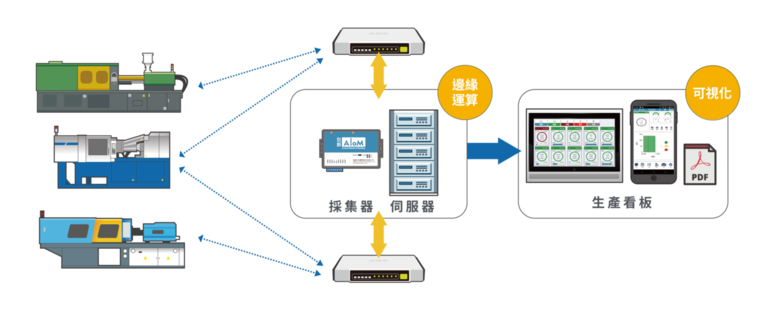

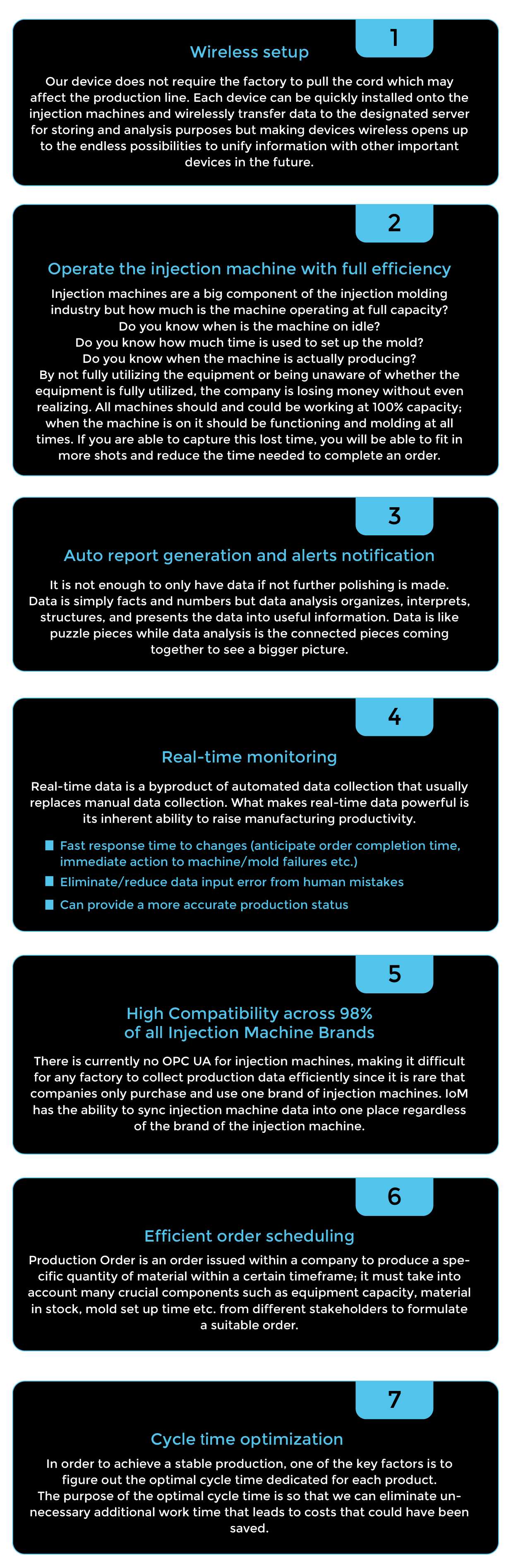

Wireless local area network design, painless deployment within 40 minutes

Support factory data networking, multi-factory information series

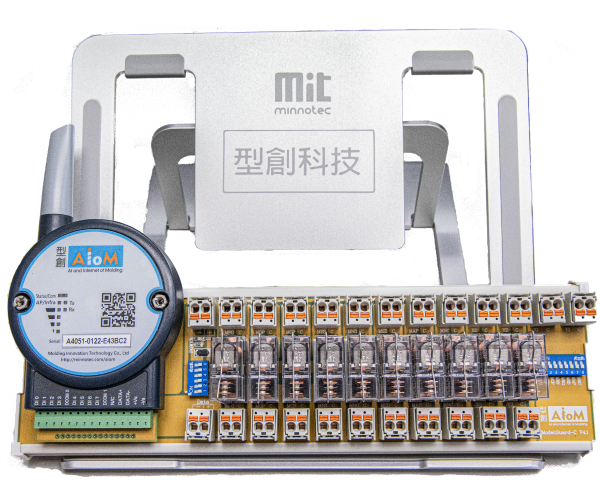

highly integrated IoT devices, automatic maintenance, and operation of machine networking

Increase in utilization rate (A)

– Real-time display of production progress

– Active notification of abnormal idle

Equipment efficiency (P) improved

– Automatically record cycle time

– Active notification of low efficiency

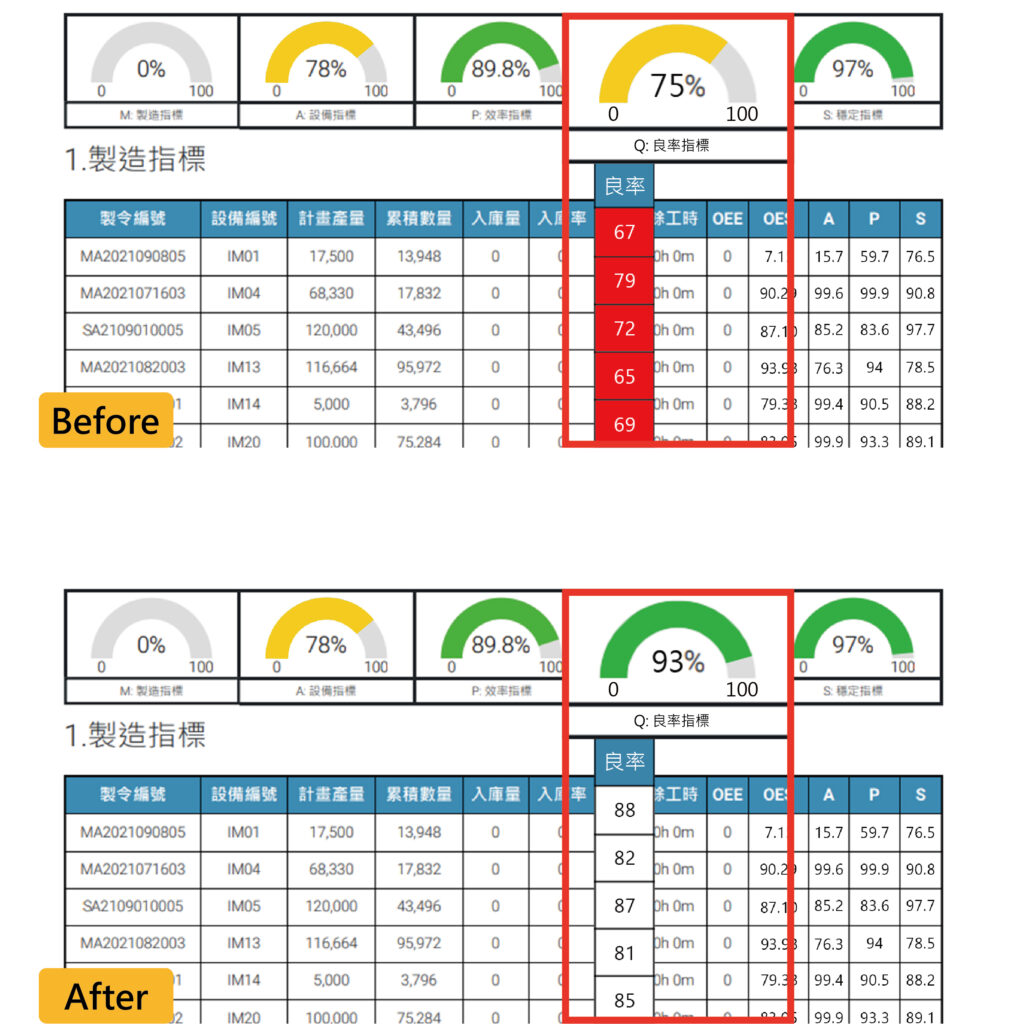

Product yield (Q) optimization

– Real-time record abnormal work report

– Proactively report the low yield rate

Bad defect records to identify potential problems

– Count the causes and quantities of bad defects, find out potential problems, and count the number of final deliverables.

– Register the reason and quantity of good products/defective products/defects, master the quality inspection/warehousing

– Customize defect reasons to meet the actual needs of the factory. Process for graded quality inspection/warehousing

– Support web page/APP, unlimited space and equipment

Standard API interface, serially connected to MES/ERP

The system adopts a standard API interface, which can be connected to MES/ERP and other systems in series, which meets the needs of factory operation management and fully realizes the digital factory.

– Provide RESTful API interface for remote access

– Adopt TCP/IP network architecture, with API service, activate remote backup

Case Studies

A number of IoM intelligent injection machine networking case sharing, sharing with you the successful road to digital transformation.

IDEC Taiwan

Before importing:

You must be present on-site to confirm the operating status of the equipment, which takes 120 minutes every day and is time-consuming and laborious.

After import:

automatically collected by the system, effectively reducing the time for processing production information and improving work efficiency by 75%.

Giga Engine Plastics Industry Limited Company

Before import:

The data cannot be mastered, and the device status can only be viewed through the monitor, which is not easy to manage.

After import:

you can instantly grasp the order progress, utilization rate, and clearly grasp the various data indicators in the factory.

LONG-SHAN MOLDING

Before import:

spend more than 2 hours every day to check the production progress on site.

After import:

remote monitoring and telephone guidance only need to be done through a mobile phone, and the efficiency is increased by more than 60%.

Office

Minnotec Thailand Co.,Ltd.

Kanya Building (A4)

999 Soi King Kaew 17, Ratchathewa Subdistrict, Bang Phli District, Samut Prakan 10540

Line official

@940ovfau

Contact number

+66 2 - 118 - 2586 (TH)

ACMT Thailand

ACMT Global