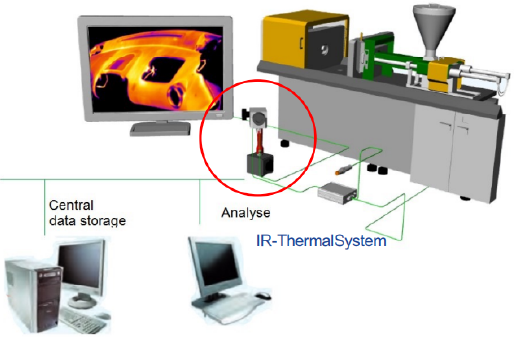

The single-seat solution directly next to the machine or the integration of one or more

cameras to the company network and central storage of data.

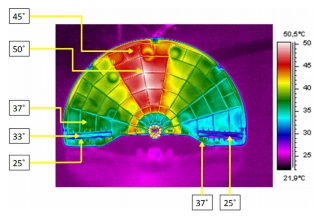

Test of local heating on the part using ceramic elements.

Influence of a thin wall section of the part.

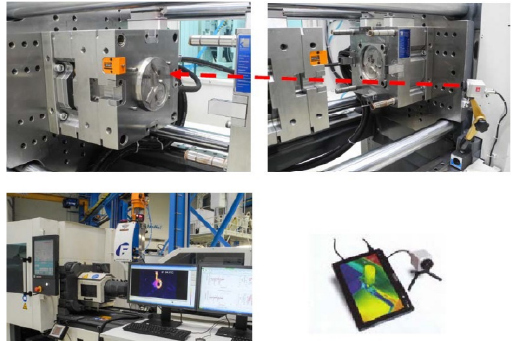

Set up of the camera with a direct view inside the open mold.

Recording of the temperature using a PC next to the injection molding

machine. Analyze of the results on a tablet using IRWeb module.

Benefits

• Able to identify both parts and molds’ temperature

• Determine the reaction time of the mold to changes

• Identify injection molding problems: sink marks, burn

marks, flashing, unfilled parts, etc.

• Identify residual material within the mold

• Identify blocked cooling channel

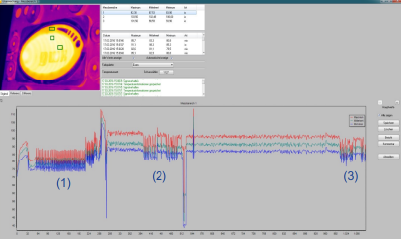

Heat and cool process (variothermal)

• Blocked filter in the cooling system / Pressure variations in

the cooling lines

• Draft through ceiling ventilation

• Draft during ceiling ventilation test for demonstration

Office

Minnotec Thailand Co.,Ltd.

Kanya Building (A4)

999 Soi King Kaew 17, Ratchathewa Subdistrict, Bang Phli District, Samut Prakan 10540

Line official

@940ovfau

Contact number

+66 2 - 118 - 2586 (TH)

ACMT Thailand

ACMT Global