Media error: Format(s) not supported or source(s) not found

ดาวน์โหลดไฟล์: https://www.minnotec.com/th/wp-content/uploads/2022/03/cover-who-we-are.mp4[Case Studies] Innovation opportunity with change

IoM Solutions, Internet of Machines Internet of Molding

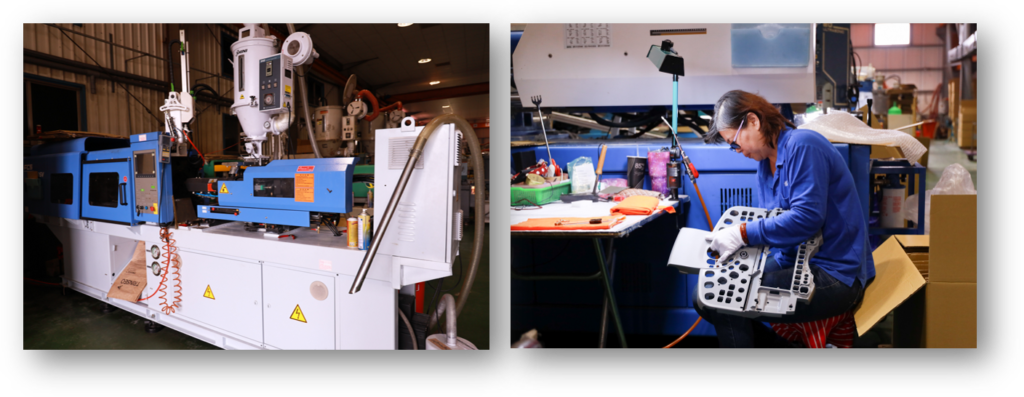

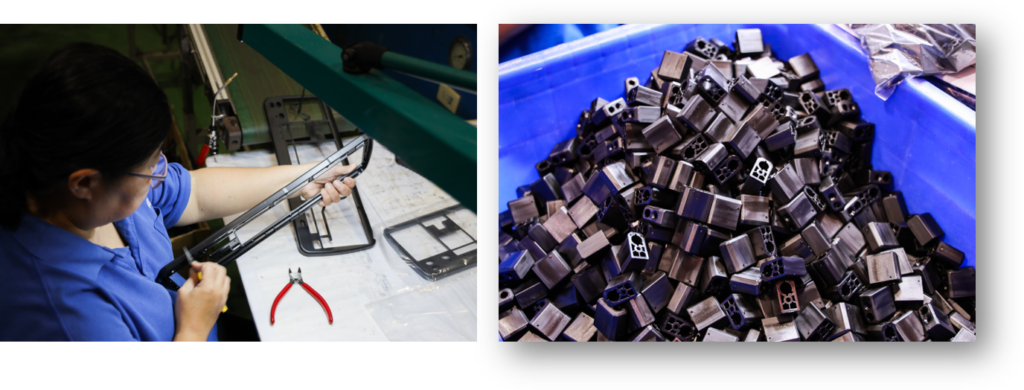

Longshan Plastic Co., Ltd. (hereinafter referred to as: Longshan Plastic), its products are mainly security, medical, and safety enclosures, and mainly focus on security and medical industries. Longshan passed the ISO9001 certification in 2002, and expanded the factory and purchased a number of injection molding machines, inspection instruments and other equipment to meet the requirements of customers and achieve stable product quality.

Taking the opportunity of change and re-innovation

Longshan Plastic provides “one-stop service”, and emphasizes credit, high mobility, and high degree of cooperation, from product design, proofing, mold opening, mold trial, production, surface treatment (painting, printing, sandblasting), assembly, packaging OEM/ODM is all completed in one window. In terms of delivery time and quality, we focus on products with a long life cycle, and expand the European and American manufacturing territory by means of trade and overseas orders. If you do it, you must be confident, take the lead in the layout and pursue transformation and development.

Improve efficiency and time efficiency by computer-assisted production

In the past, there was no monitoring of the operation of the whole factory, and it often took a lot of time to copy data manually. There was a gap between the actual situation and the record. Therefore, I hope to introduce the “Internet of Things” to monitor and manage in time, and use the Internet of Machines technology to quickly grasp the cycle. At the same time, based on such a foundation Moving towards real-time production and deployment, collecting real-time and correct data, assisting management through Kanban monitoring, and improving efficiency by computer-assisted production, there is no need to spend more manpower to record, this step-by-step process can be practiced step by step.

Why do factories choose IoM

I realized the focus of the consulting team in the plastics field and the professionalism of mold flow analysis a long time ago. For the previous successful cooperation experience, when facing the challenges of digital transformation and changes, I would also give priority to whether the company has corresponding solution.

After equipment research and factory planning, Xingchuang confirmed that it can be executed, and it was delivered with confidence. In the end, all our different brands of injection machines were successfully networked.

Longshan is the first few factories to carry out the Internet of Things. We are also very happy to face challenges and grow together with our partners. After this cooperation experience, we have a very positive evaluation of Xingchuang, so the future transformation will continue. Hand it over to Type Creation for processing.

Free up time, focus on quality

Before the introduction of the Internet of Molding (Internet of Molding), it took more than 2 hours every day to go to the site to check the production progress. After the introduction of the Internet of Molding, it only needs to use the mobile phone to remotely monitor and provide guidance. The efficiency is increased by more than 60%, and even if people are outside, there is no need to worry about whether the factory is in a condition, and instead it adds a lot of management and quality value, so that the product delivery time is on schedule, or even earlier.

Office

Minnotec Thailand Co.,Ltd.

Kanya Building (A4)

999 Soi King Kaew 17, Ratchathewa Subdistrict, Bang Phli District, Samut Prakan 10540

Line official

@940ovfau

Contact number

+66 2 - 118 - 2586 (TH)

ACMT Thailand

ACMT Global