Stress Viewer

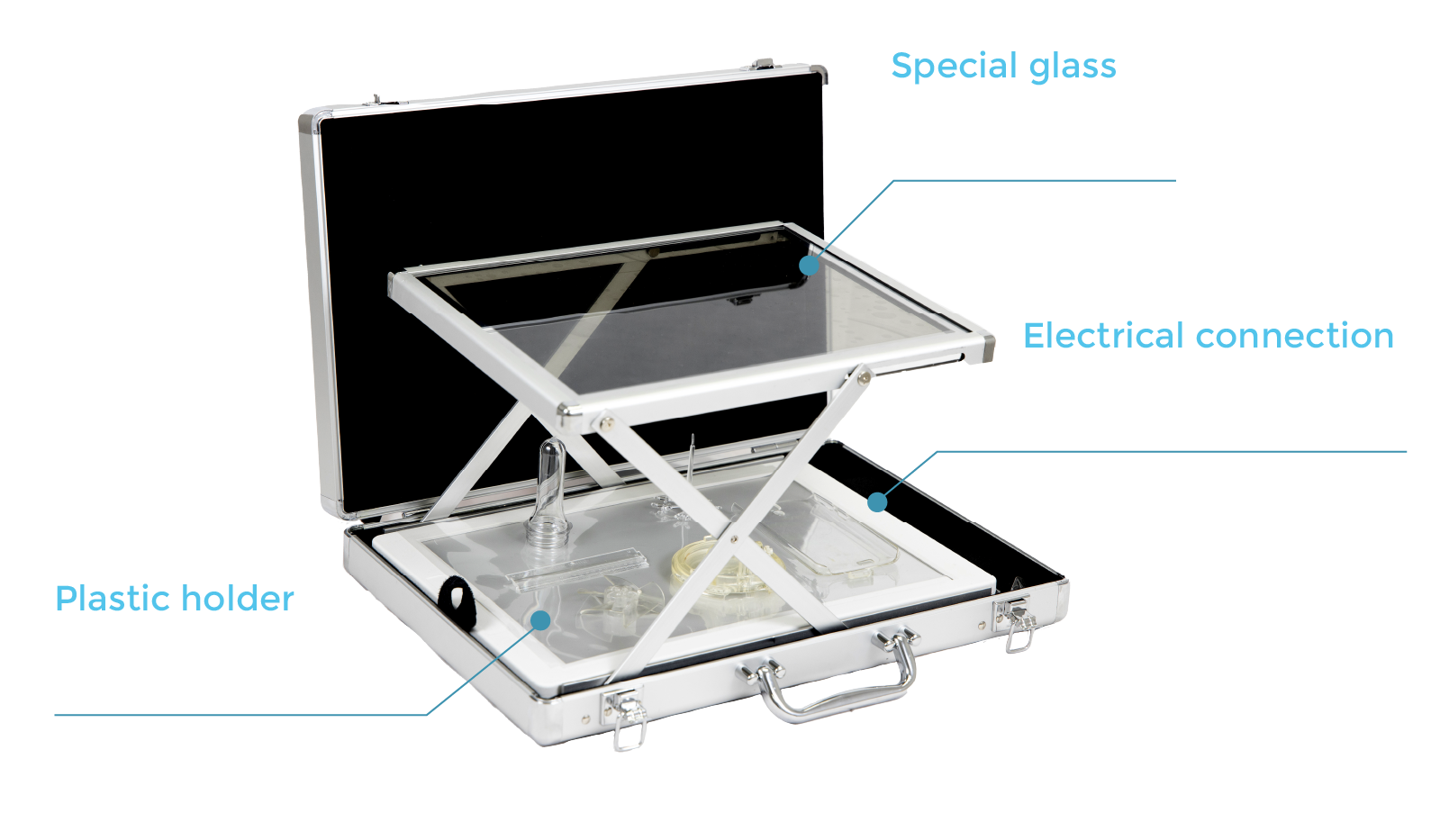

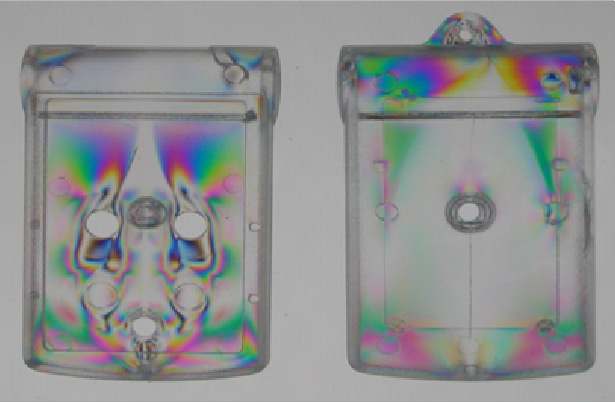

The penetrating stress polarizer is a non-destructive qualitative observation measurement device, which uses the birefringence property of the plastic molecular structure under the action of stress to observe the change of the photoelastic properties of the plastic part. As long as the transparent plastic or light-transmitting product or test piece is placed in the observation window, the white light source can be deflected through the polarizer by the plastic birefringence and photoelastic properties to form visually observable colored stripes. The displayed stripe form and stripe density can observe the degree of residual stress inside the plastic part.

Through the penetrating stress polarizer, the internal residual stress of plastic parts can be quickly and easily detected, and the stress distribution can be further understood. Through professional technical interpretation, feedback, and consulting services, the causes of residual stress can be found early and suitable solutions can be provided. , optimize mold design and plastic product quality.

Used to quickly check

the stress of plastic parts.

Can be used with

all typesof clear plastic parts.

Stress Polarizer – Features

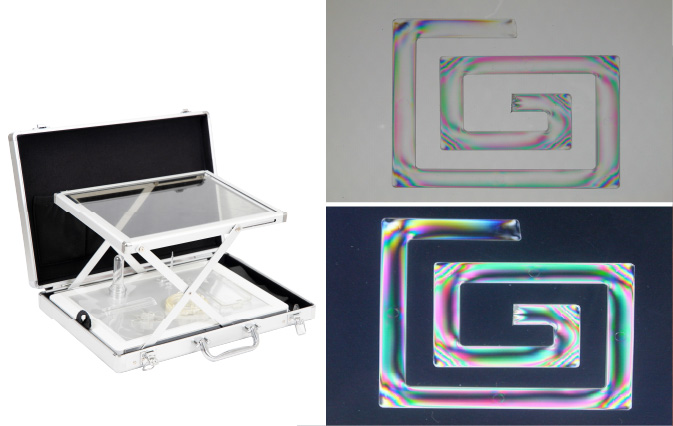

Instant observation of residual stress distribution

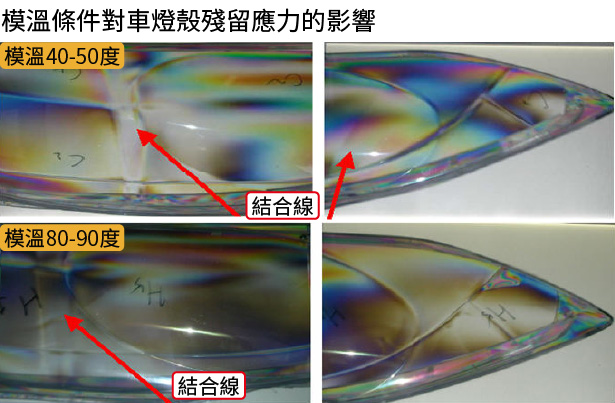

By means of the plastic birefringence and photoelastic properties, the white light source is deflected by the polarizer to form colored stripes. From the displayed stripe form and density, the degree of residual stress inside the plastic part can be observed.

The part with higher stripe density is the area with higher residual stress of the plastic part.

Stress Polarizer – Benefit

Stress distribution at a glance

Instant detection next to the machine

Grasp the influence of molding parameters setting on stress and reduce residual stress in finished products

Grasp the influence of molding parameters setting on stress and improve the adhesion of post-processing

Stress Polarizer – Advantages

– Non-destructive transmissive polarizing technology.

– Direct observation of residual stress distribution of plastic products.

– The backlight light source module is suitable for all kinds of transparent plastic parts.

– Portable design, lightweight and easy to carry, ready to use next to the molding machine.

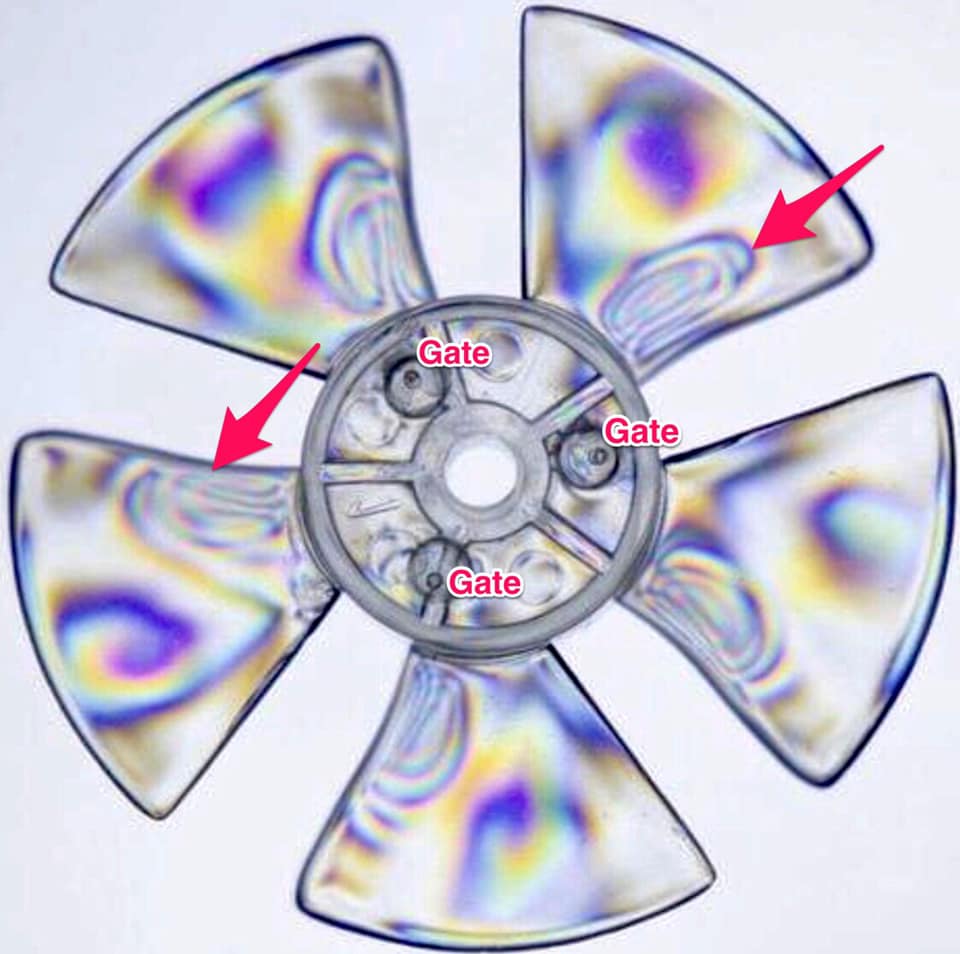

Part: Fan

Issue: Noise when running the fan.

Reason: Unbalanced flow with the gate position.

Checking equipment: SV-Stress Viewer

What are the applicable materials that can be observed?

Transparent materials or light-transmitting outgoing plastic parts can be observed.

If the material is opaque, how can the residual stress be observed?

Stress analysis can be performed using mold flow analysis software.

How to get a stress polarizer?

You can contact us through the contact window below, or leave your contact information, and someone will reply and provide you with services as soon as possible.

Office

Minnotec Thailand Co.,Ltd.

Kanya Building (A4)

999 Soi King Kaew 17, Ratchathewa Subdistrict, Bang Phli District, Samut Prakan 10540

Line official

@940ovfau

Contact number

+66 2 - 118 - 2586 (TH)

ACMT Thailand

ACMT Global